Technology

Varial Foam

Varial Foam is the world’s first high-performance foam adapted from advanced aerospace materials for surfboard construction. It's new foam chemistry which focuses on improving the performance of the surfboard core while increasing strength and longevity. The high modulus of Varial Foam makes it 25% lighter and 40% stronger than a PU blank with a stringer. It provides a strong and lively foundation on which shapers can incorporate any flex option they desire.

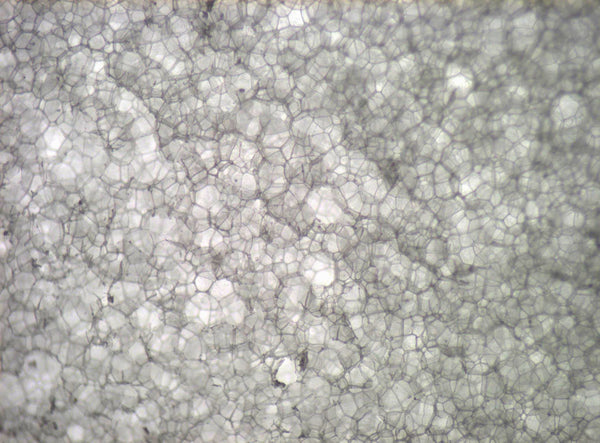

Our extremely tight cell structure and uniform density enhance the board building process, eliminating variables which negatively affect a board’s performance. Varial foam is 100% UV resistant and will never yellow. Varial foam can also be glassed with polyester or epoxy resin.

Check out our 4 point bend test in the video below. We tested the bending strength of Infused Glass in polyester and epoxy resins, with various layups on both Varial Foam and PU cores.

Infused Glass

Varial has created a new patent-pending process for glassing boards, called Infused Glass. Drawing on our core competencies of adapting aerospace technologies for the advancement of surfboard performance, Varial has developed a revolutionary vacuum bagged glassing product. The process, currently used to make large wind turbine blades and racing boat hulls, infuses polyester or epoxy resin into the fiberglass under vacuum pressure in one shot. This produces a uniform laminate that’s tight to the shape with extremely low resin content. We then have the ability to isolate and engineer specific characteristics into the skins of the surfboard for any desired performance attributes.

Learn more about our vision here.