One of our most frequently asked questions is about the difference between epoxy and polyester resin in our technology. Varial Foam is compatible with both resin systems, so when getting a Varial surfboard you’ll be faced with this decision. The purpose of this article is to make that decision easier by giving you a full rundown in a way that’s easy to digest. Unless stated otherwise, in this article we’re only referring to surfboards made with Varial Foam cores.

So which is the better resin to use? Bottom line is that you can’t go wrong with either, but there are some key differences between the two resin systems. Especially in terms of flex and durability.

Cost - Epoxy resin costs more than polyester resin and therefore requires an upcharge. If you buy your custom through our website the upcharge is $70. Most other surfboard manufacturers charge $100-$150 for epoxy.

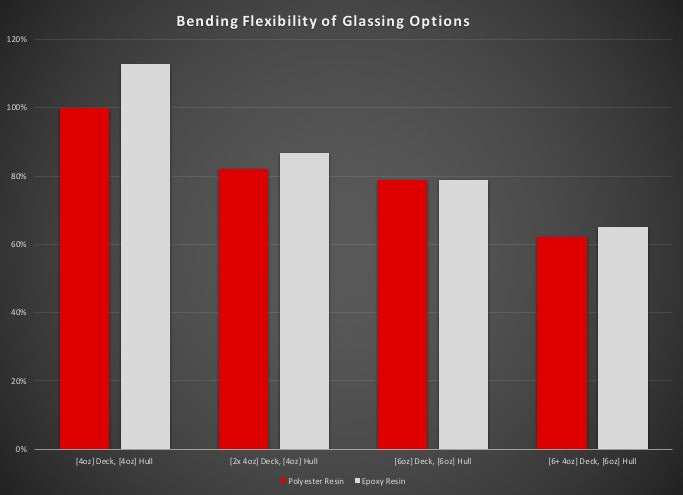

Flex - Polyester resin is a stiff resin system and epoxy is more flexible. This means that a polyester resin board will have a little more stiffness and drive while an epoxy resin board will have slightly more flex and pop. How much more flex? We performed controlled 4-point benchtop tests to answer that question.

4 point bend test on sample panels with different glassing layups, each in polyester and epoxy resin.

This fact dispels a common myth that epoxy boards are stiffer than polyester boards. That myth most likely came about because so many epoxy resin boards are built around soft EPS cores. Those cores require more glass, carbon fiber and often high-density sandwiched foam sheets to be strong enough to surf. All of that added reinforcement makes the boards stiff. This is not the case with Varial Foam, which makes boards 40% stronger than traditional surfboards and does not require a stringer or other stiff reinforcements.

So what flex is best? Epoxy or Polyester? It's really a matter of personal preference and depends on your riding style. All of the professional surfers who ride our tech get their boards glassed with polyester resin; they’re accustomed to the flex of polyester resin and appreciate the added drive. However, you might not be charging powerful North Shore waves and instead looking to get the most zing out of your turns in average conditions. In that case, epoxy probably has the flex you’re after.

Chatter- A lot of people worry that their board will chatter if they get it glassed with epoxy. That’s not the case. The rigidity of the Varial Foam core will cut through chop much better than any other type of surfboard foam. Don’t worry about chatter when designing your board. Either resin system on Varial Foam will handle chop better than anything else you’ve ridden.

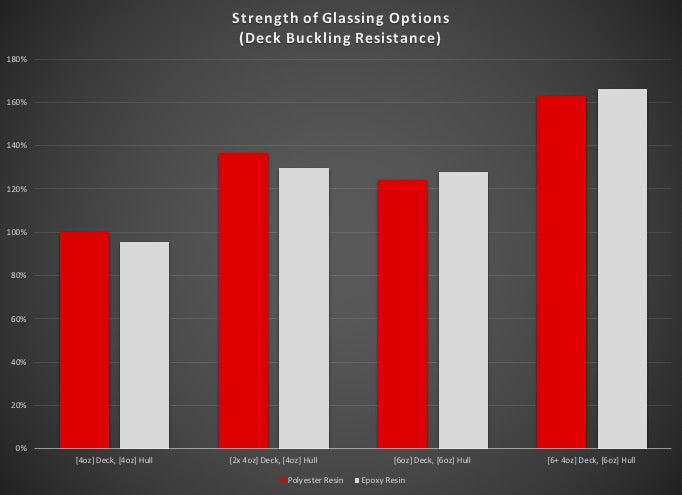

Board Buckling Strength - We’ve done extensive lab testing and found no meaningful difference between the buckling strength of boards glassed with epoxy versus polyester resin. The more fiberglass you get on your board the stronger and stiffer it will be. Keep strength in mind when selecting the amount of fiberglass, but don’t worry about it for resin selection.

Durability - Here’s a category where epoxy is the clear winner. The high bonding strength of epoxy combined with its increased flexibly makes it much more resistant to everyday wear-and-tear dings. Nothing is more frustrating that dreaded secondary click you hear when you accidentally smack your board into something. If you’re like me and clumsy with your surfboards the added ding resistance of epoxy will pay off. I get all my boards glassed with epoxy for this reason.

Whiteness - Here’s another category where epoxy wins out. The natural color of Varial Foam is eggshell white. While Varial Foam is 100% yellow proof from sunlight exposure, some people want their new board to be as white as possible. If that’s the case for you, you’ll want to pick epoxy resin. To make it blindingly-white put in a special request to upgrade your fiberglass to S Glass. The cost will be based on the exact dimensions and layup schedule of your board. S Glass fiberglass is 42% stronger than E Glass and also 24% stiffer, so changing the cloth will definitely have performance and strength implications for your board.

Sustainability - We use Entropy BRT Super Sap resin as our epoxy resin for all the boards we glass with our Infused Glass vacuum bag process. This resin contains 21% biobased carbon content which makes it that much more sustainable than other resins. However, the main reason we use Entropy resin is because it’s an excellent resin system designed specifically for performance surfboard applications. It’s rare to find a sustainable material that also has best-in-class performance, but Entropy has accomplished just that. Desi and the crew provide us with excellent customer service and technical support. We’ve worked closely with them over the past few years to dial in this resin system for our Infused Glass process.